How to Use a Tap: 13 Steps

1. Gather materials: To use a tap, you will need a tap wrench, the proper size tap, and cutting oil. Make sure you have all the necessary tools before starting the process.

2. Select the correct tap: Taps come in various sizes, so it’s essential to choose the right one for your project. Measure the hole and consult a drill and tap chart to ensure proper thread engagement.

3. Choose or create a pilot hole: Before tapping a threaded hole, drill a pilot hole with the appropriate-sized bit to match the tap’s size and thread count.

4. Apply cutting oil: Cutting oil helps reduce friction, prevent overheating, and prolongs tool life. Apply cutting oil generously to both the hole you’re tapping and the tap itself.

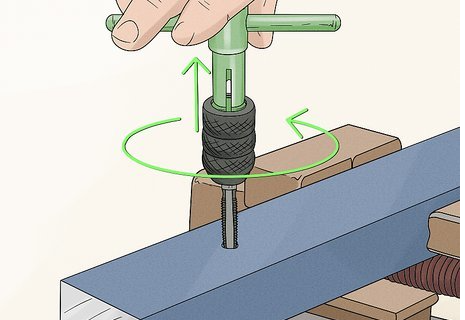

5. Insert and align the tap: Place the squared end of your chosen tap into your tap wrench’s jaws and tighten securely. Carefully align the tap with the drilled hole, ensuring that it is perpendicular to your workpiece.

6. Begin tapping slowly: Apply gentle firm pressure on your tap wrench handle while turning it clockwise in a right-handed thread configuration or anti-clockwise direction for left-handed threads. This will help create new threads within your drilled hole.

7. Ensure proper threading: After every half-turn or so, turn your tap wrench counter-clockwise a quarter turn to break loose and clear any metal chips that accumulate during tapping.

8. Continue cutting threads: Keep rotating your tap wrench clockwise in small increments, pausing occasionally to clear metal chips with a reverse spin of the tool.

9. Monitor progress: As you continue tapping, periodically check that you are maintaining an even depth of threads and that there is no binding between the tool and workpiece.

10. Approach completion: As you reach your desired thread depth or near the bottom of a blind hole, ease off on applied pressure while still turning clockwise.

11. Remove the tap: Once tapping is complete, carefully reverse the rotation of your tap wrench to back out the tool from the threaded hole.

12. Clean and inspect: Thoroughly clean any cutting oil, metal chips, or debris from the threaded hole and tap, then inspect for any defects or cross-threading that may have occurred during tapping.

13. Test fit the mating part: Thread a matching fastener or component into your freshly tapped hole to ensure smooth engagement and proper fit.

By following these 13 steps, you can confidently use a tap to create new threaded holes or repair damaged threads in your projects. This essential skill will open up various fabrication and repair options for the DIY enthusiast or professional tradesman alike.